spray drying temperature

Spray drying often is used as an encapsulation technique by the food and other industries. Therefore according to the isothermal adsorption curve increasing the gas temperature of the inlet may shift the conditions of the outlet of the drying tower from the.

Effect Of Spray Drying Temperature On Physicochemical Antioxidant And Antimicrobial Properties Of Pectin Sodium Alginate Microencapsulated Carvacrol Sciencedirect

Although insulin begins to degrade at temperatures higher than 40 C it was possible to overcome this hurdle.

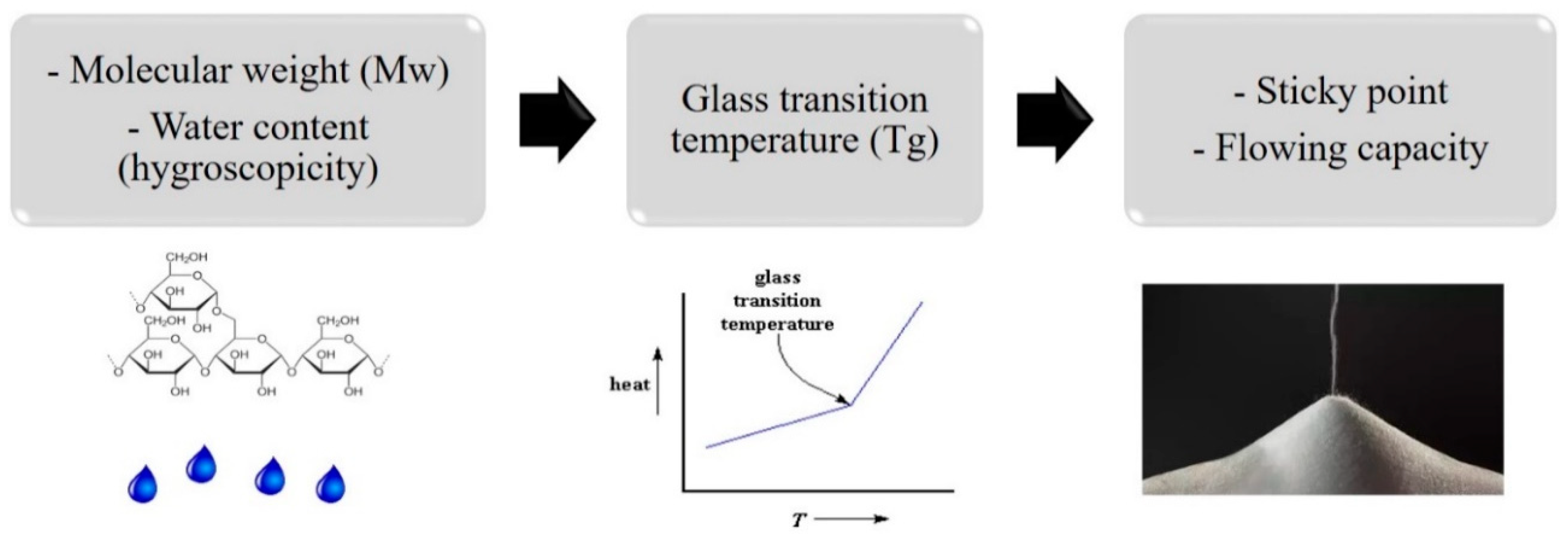

. Spray drying might potentially cause particle aggregation due to high temperatures shear forces and partial melting of the particles. Dry bulb temperature td is the temperature of air which is not saturated with water vapour as measured by an ordinary thermometer. The spray drying parameters were optimized by considering saponin content and foam volume by response surface methodology.

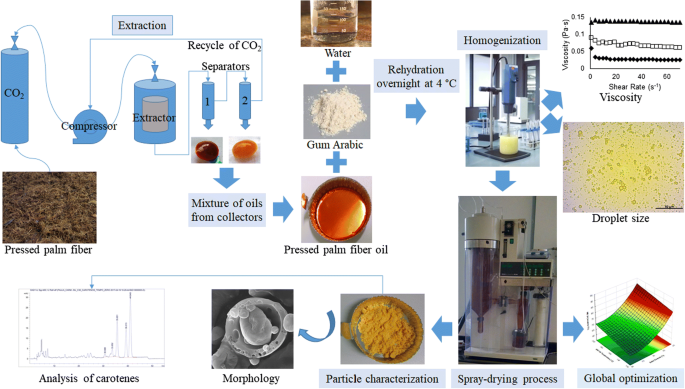

As the slurry enters the tower it is atomized. According to the numerical optimization optimum feed. Inlet and outlet spray-drying temperatures of 140 and 80 C were optimised by RSM.

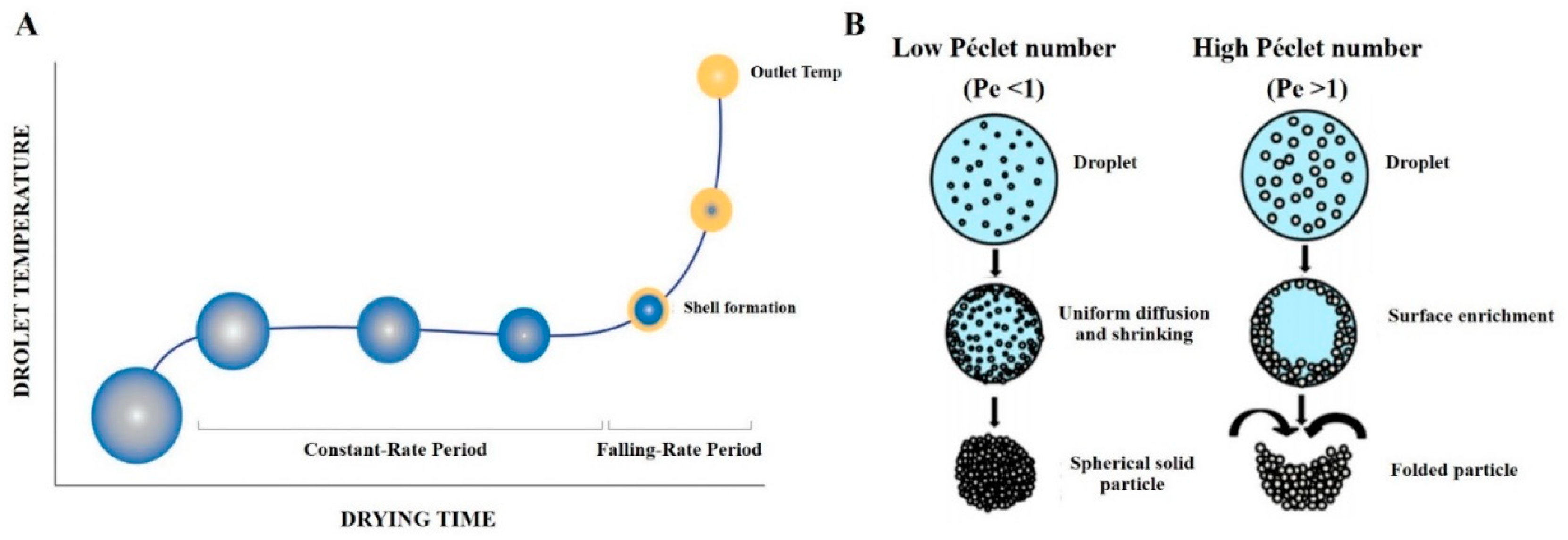

During the first stage the temperature in the saturated air at the surface of the droplet is approximately equal to the wet-bulb temperature of the drying air. If the room in which the ves- sel is situated is 80F there is enough temperature. Freitas and Müller 1998b recommend the use of lipids with melting points 70C eg tribehenin 72C for spray drying.

At 25 C. You could control the air temperature in the heat exchanger before feeding to the spay dryer then only. Partly because of the high surface tension of water.

There is sufficient moisture. To introduce our modelling approach the known and unknown air parameters in a spray dryer are represented in Figure 3. In spray drying systems the exhaust air temperature or humidity provides an input.

YC-1800 Low Temperature Spray Dryer Minimum inlet air temperature is 105 C minimum air outlet temperature is 60 C. For a process with a 160180F dryer outlet temperature dew points can be in the range of 120130F. You must decrease the time leg to improve your spray drying process.

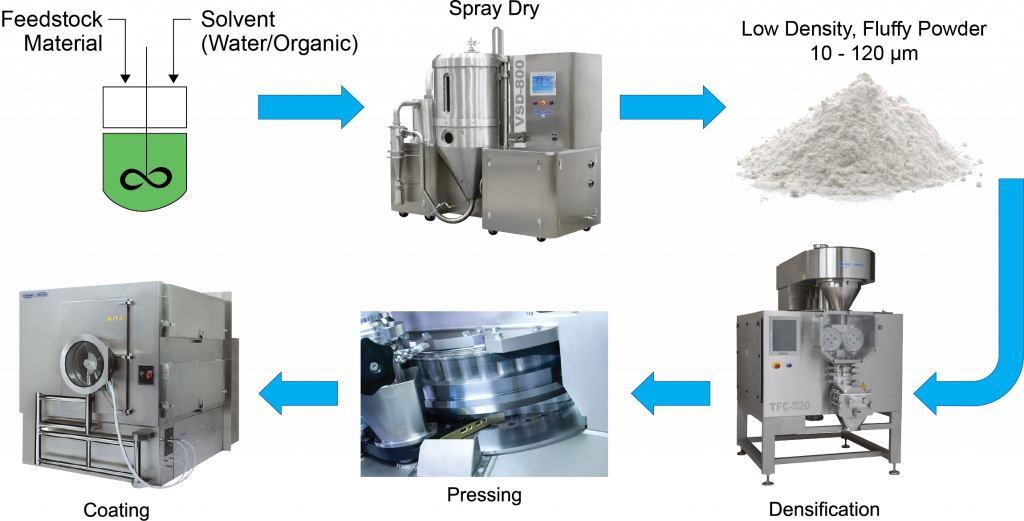

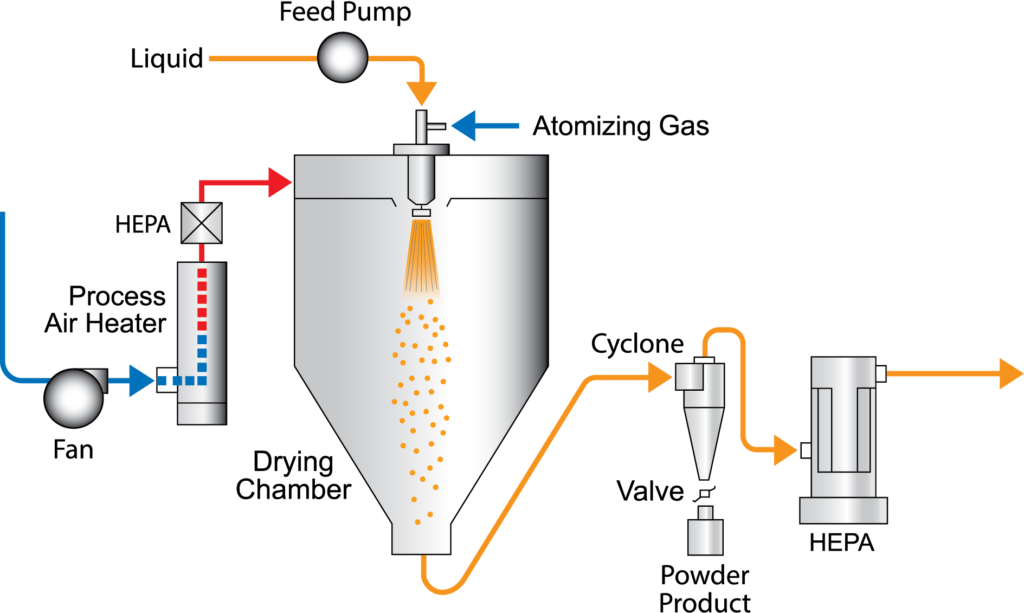

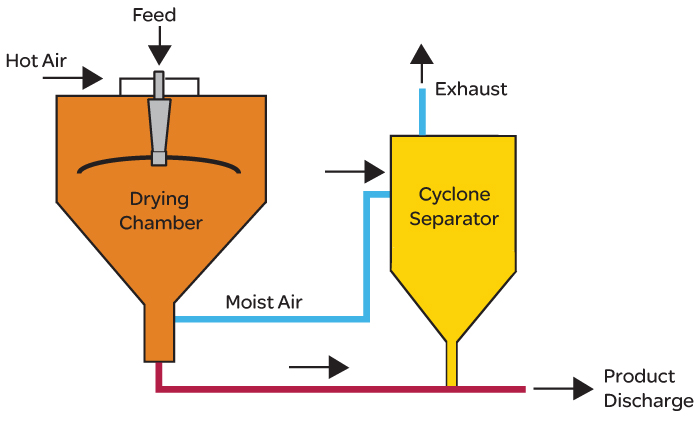

The drying chamber is a mixed structure of SUS304 stainless steel. Three points are very important in characterisation in. Spray drying involves atomising the feed into a spray of droplets which are put into contact with hot air in a drying chamber.

The slurry is then fed into a spray drier usually a tower heated to temperatures above the boiling point of water. Low-Temperature Spray Drying Zoom Essence is a flavor company in New Jersey that claims to offer superior flavors encapsulated oils soluble coffee and active. Prior to spray drying the slurry must be processed at the right temperature viscosity and other parameters depending on the application must be reached for example a Total Solids - Ts -.

A bitter melon aqueous extract was successfully encapsulated by spray-drying. Spray drying is a well-known method of particle production which consists on the transformation of a fluid material into dried particles taking advantage of a gaseous hot drying. Spray drying was identified as the gentlest way to achieve this.

There are three modes of contact. A substance to be encapsulated the load and an amphipathic carrier usually some sort of modified starch are homogenized as a suspension in water the slurry. Spray dryers are controlled by programmable logic controllers PLCs or solid-state controllers.

In practice the dry bulb is just referred as air.

Spray Drying Of Dairy Products A Review New Food Magazine

Effect Of Solids Content And Spray Drying Operating Conditions On The Carotenoids Microencapsulation From Pressed Palm Fiber Oil Extracted With Supercritical Co2 Springerlink

Spray Drying Process An Overview Sciencedirect Topics

Spray Dryer Chamber Design How Is The Diameter Of The Evaporator Chamber Calculated

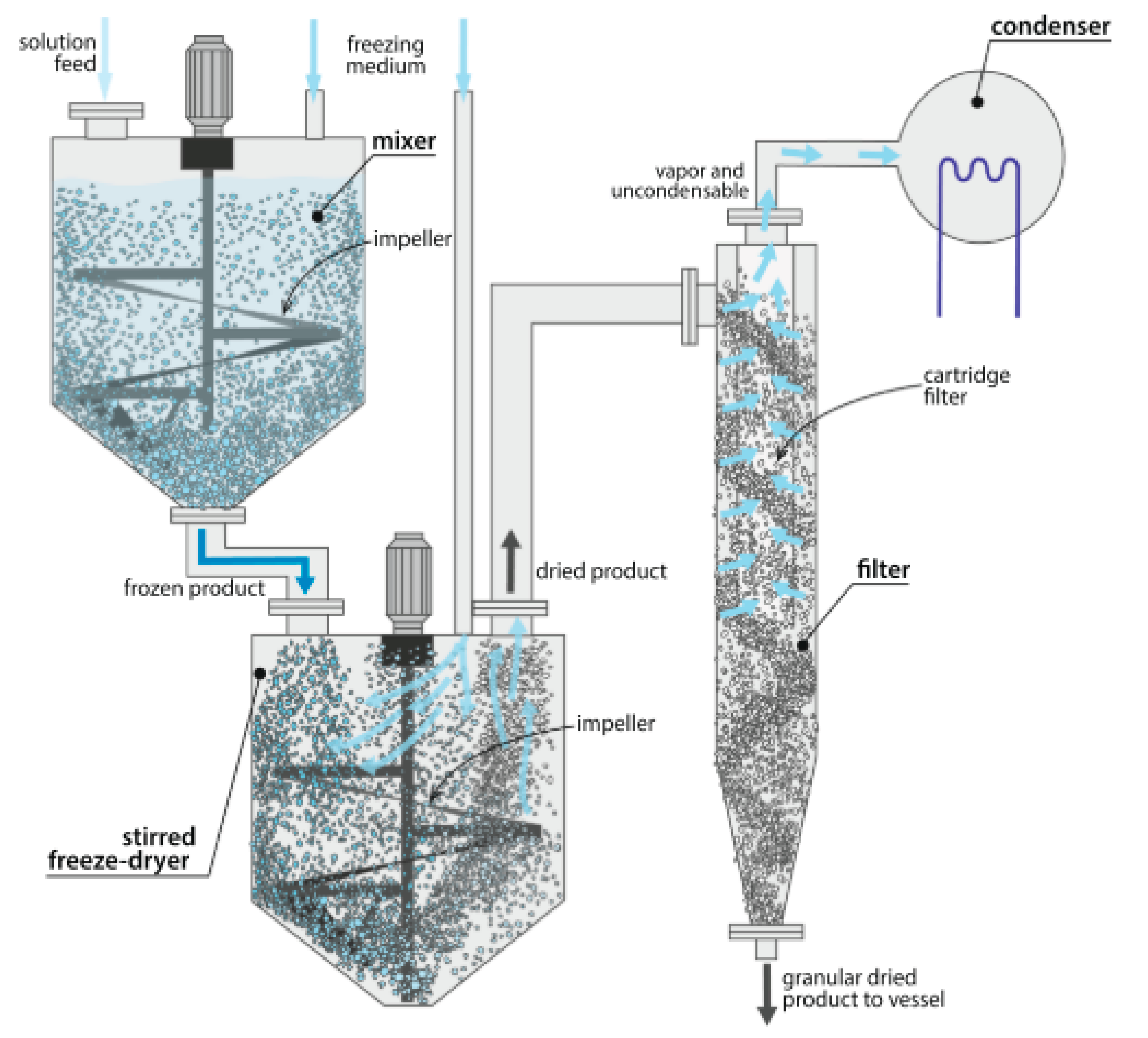

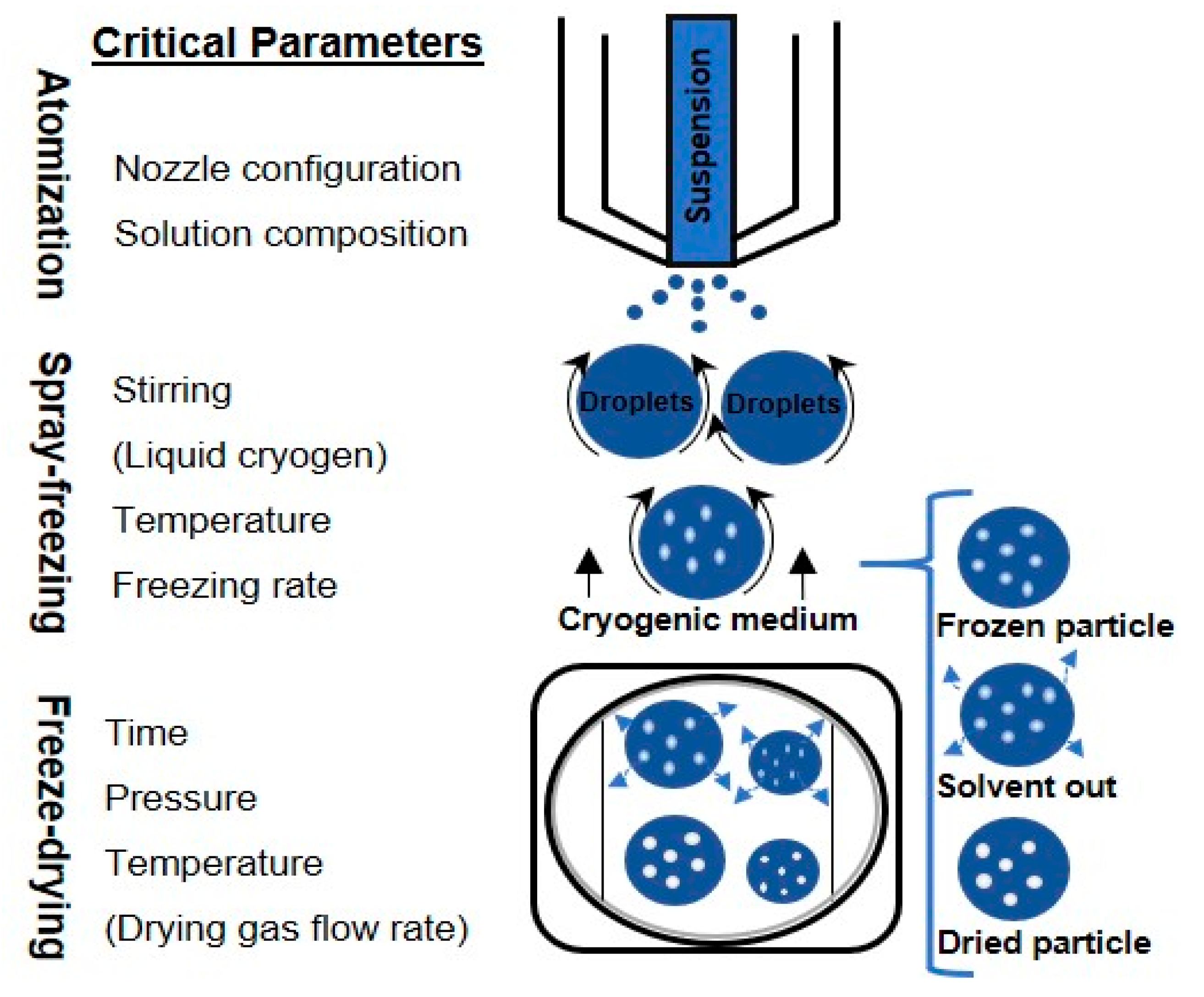

Processes Free Full Text Spray Freeze Drying As A Solution To Continuous Manufacturing Of Pharmaceutical Products In Bulk Html

Spray Dryer An Overview Sciencedirect Topics

Pharmaceutics Free Full Text Influence Of Composition And Spray Drying Process Parameters On Carrier Free Dpi Properties And Behaviors In The Lung A Review Html

Processes Free Full Text Spray Freeze Drying As A Solution To Continuous Manufacturing Of Pharmaceutical Products In Bulk Html

Spray Dryer Operating Principles Process Layout Uses Advantag

Spray Drying Moisture Challenges Industry Applications Bry Air

The Drying Curve Part 1 2002 09 01 Process Heating

37 Questions With Answers In Spray Dryer Science Topic

Pharmaceutics Free Full Text Influence Of Composition And Spray Drying Process Parameters On Carrier Free Dpi Properties And Behaviors In The Lung A Review Html

Comments

Post a Comment